CONCEPTS OF RELIABILITY ENGINEERING (RE)

FOR THE COMMON MAN

Dr. I. Achyuta Rao

“Do not have the apprehension

That RE is beyond your comprehension”

—An unknown scientist

Reliability

engineering (RE) is the ultimate in engineering techniques. It is applicable to

all branches of engineering and technology. It leads to the “state of absolute

perfection” in the relevant fields. If proper care is exercised, it is

applicable to bioengineering and biotechnology also. It is extendable to the

fields of surgery, medicine and pharmacy. The common man, as the user, is the

prime beneficiary of RE techniques, hence the need for publication of this

article in this journal.

We buy many

household articles in the market. They fail to work immediately after bringing

them home or after a few days or months of usage. We have to get them repaired

or replaced. It becomes a nuisance some times. An item does not work when we

want to use it. Even if it works for some time, it fails at the most crucial

moment. That means, the item does not have adequate “RELIABILITY”. The concept

of warranty/guarantee arises, only out of this unpleasant experience.

On the other

hand certain items work without fail for hours or even days and months. In

extreme cases they work “failure free” for years at a stretch. We reach a

sublime state or heaven. Such items are stated to have high reliability (R).

The common man wants high R of all items, to lead a pleasant and peaceful life.

That is why the craze for “foreign goods” arose, of late.

(During

World War II cheap Japanese goods flooded the Asian market. They used to fail

miserably and people used to call them “Japanese Products” meaning of low

reliability. After the war, Japan

developed the RE field so much, that their products are the best and most

reliable items today. Now the Chinese

goods have flooded our markets).

Some items

are repairable or maintainable. After repair or maintenance, they continue to

work “failure free” for months or years. I do not wish to dwell on this aspect

here but cover the generic term R.

Definition of Reliability (R)

Then what is

Reliability? It is a concept statistically defined as “the probability that an

item performs its intended function, under stated environmental conditions, for

a given time of operation”.

Notionally,

if the item is not expected to fail ‘at all’ during that specified time, the R

is I. If it is sure to fail during that time, the R is O. The actual

(probability or) reliability value lies between these extreme values 0 and 1.

The R of an

item depends essentially on its failure rate (F). If the failure rate is low,

reliability R is high and vice-versa. In order to have high R, the item should

have low failure rate, by design and careful manufacture. The scientific

expression for reliability is

R =e -Ft

where, “t” is time of operation. In fact, R falls off exponentially with

increase of time. Note that the fall is not due to wear and tear with time

(since it occurs even if the F is constant). Of course wear and tear cause

increase of F, which causes lowering of R., as explained earlier.

Failure Rate (F)

Failure rate

(F) is the reciprocal of the time an item or component takes to fail, on an

average. If it takes ten minutes to

fail, F is 1/10 per minute.

Probability Concepts

The failure

rate (F) is an average value taken over several tests. The item may not fail at

the average value of time recorded. It may fail at any time before that or

after that, hence the need for introducing probability concepts.

If an item

contains two components whose failure rates are FI and F2, the reliability R of

the item is the product of component reliabilities

R=e-F1t x e-F2t

= e-(F1+F2) t

It is obvious

from the above that the failure rate of the item is the sum of failure rates of

the two individual components, because anyone of the two components may fail at

any time.

If an item

contains a number of components (say 10) the failure rate of the item is the

sum total of the failure rates of all the (10) components. So, if the number of

components is larger, the failure rate of the item is higher and its

reliability lower.

One

understands, that the simpler the item (containing a smaller number of

components), higher the R and for a complex item (containing larger number of

components) lower the R.

New and

un-established technologies have high failure rates and hence low R values. Once

the technology is perfected, the failure rate becomes lower and R value higher.

Number of Tests for R-Estimation

A suitable

number of an item is taken for (performance) tests (under stated environmental

conditions) and the number that passed the test is recorded to estimate R.

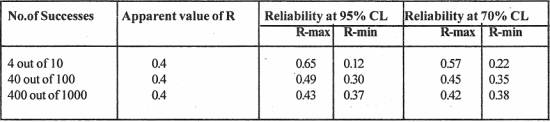

If 4 out of

10 tests resulted in total success, the R is 0.4

If 40 out of

100 tests resulted in total success, the R is still 0.4 (but with greater

confidence level.

If 400 out of

1000 tests resulted in total success, the R is still 0.4 (but with still

greater confidence level (Partial success is not considered for R estimation).

Confidence Levels (CL)

Thus the

statistical confidence levels are introduced to bring in more realistic

estimation of R.

If we fix our

confidence level at 95%, the above three sets of results give different values

of R. In fact, one upper limit and one lower limit are given for each set of

results indicating a range of values based on the probability.

If we fix our

confidence level at 70% the three values of R-limits are closer, as seen in the

above table. For both the CL’s, R-max and R-min are closer in the case of large

number of tests. They tend to merge at

0.4, when the number of tests tends to 00.

The lower

limit is the criterion for accepting the item based on tests. (100% confidence

level is purely notional but not practical).

This brings

to our appreciation that the number of tests on an item (or the number of

identical items tested) should be as large as possible to get a realistic value

at adequate confidence levels. It is up

to us to specify the CL depending on the situation and our requirement.

During my

short visit to United States, I happened to study a number of research papers

published in the fields of medicine and pharmacy, based on as small a sample

size or number of tests) as 15 to 25. It is grossly inadequate to give any

reasonable confidence level, say 60 to 90%. Often, the earlier conclusions

based on limited tests were reversed based on results of more extensive tests.

Concern for Reliability

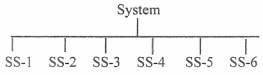

Suppose a

complex system like a Guided Missile or Satellite Launch System (one shot or

non-repairable systems) consists of 6 sub-systems.

Failure of

anyone sub-system will cause failure of the entire system. The reliability RS

of the total system is the product of the individual reliabilities of the 6

sub-systems.

Rs=

R1.R2.R3.R4.R5.R6

For example,

Rs = (0.9)

(0.9) (0.8) (0.8) (0.9) (0.8) = 0.37

If each

sub-system has 4 assemblies, the reliability Ri of the sub-system is

the product of the individual reliabilities of the 4 assemblies.

Ri

= a1.a2.a3.a4 where ai

is the R of an assembly. For example,

Ri

= (0.97) (0.97) (0.98) (0.98) = 0.9

Similarly, if

each assembly has 5 sub assemblies, the reliability ai of the

assembly is the product of the individual reliabilities of the 5

sub-assemblies.

ai

= r1.r2..r3.r4.r5 where

ri is the R of the subassembly.

For example,

ai = (0.996) (0.996)

(0.996) (0.996) (0.996) = 0.98

Thus we can

go further down to individual components.

A complex

system like a Guided Missile may have one million components. Imagine the

probability of the system failure due to failure of anyone of the million

components. This poses the questions; a) how do we go about designing for the

specified system reliability Rs and then achieve it in practice? b)

how do we evaluate the R-design and then demonstrate the achieved reliability Rs?

Redundancy

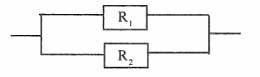

In the case

of highly critical sub-systems/components or where the specified reliability

cannot be achieved in practice (when we reach the ultimate), redundancy is

introduced on the principle of parallel circuits.

R = 1- (l-R1) (l-R2)

Where I-R1 is the probability of upper block

failure

I -R2 is the probability of

lower block failure

(l-R1)(l-R2) is the

probability of both of them failing.

R is the probability of both of these not

failing (at least one will work)

If R1 =

0.7 and R2 = 0.8, R is 0.94, higher than both R1 and R2.

“RE” Techniques

R-Apportionment to sub-systems, assemblies and sub-assemblies

R-Design evaluation methods

R-Test methods

- Destructive and Non-Destructive tests

- Time terminated tests

- Failure-terminated tests etc.

Fault- Tree Analysis

Statistical sampling techniques

R-Block diagram

R-Demonstration

R-Growth models etc,

are beyond

the scope of this article. However, the basic concepts of interest to the

common man are indicated.

How To Make A Reliable Item/System

1) Make

the item simple. (Minimise the number of components)

2) Use

good quality materials (follow national and international standards

3) Use

only established technologies

4) Use

components with low failure rates (follow various standards)

5) Carry

out extensive tests to eliminate

a) Design deficiencies

b) Defective components

c) Defective and non-standard materials

and improve intrinsic reliability

6) Keep

the operational environmental conditions in view while choosing the materials, processes and components

7) Introduce

redundancy wherever essential

8) Train

the workers to high-skill level

9) Educate

the workers to appreciate high quality requirements

10) Motivate

the workers for full participation, devotion, dedication and responsibility

11) Educate

the workers on the concepts of RE and their appreciations

One should

remember the SAYING

For want of a

nail, a shoe was lost

For want of a

shoe, a horse was lost

For want of a

horse, a rider was lost

For want of a

rider, a battle was lost

For want of a

battle, a war was lost

Tasks Involved

However, it is not an easy task to

- Specify appropriate reliability Rs to a complex

system

- Design the system for the specified Rs

- Apportion sub-system, assembly and sub-assembly

reliabilities (Ri, a i, and ri)

- Achieve them in hardware fabrication-Demonstrate them by

proper tests

- Maintain them in bulk manufacture

- Prove them by conduction of sample tests

- Finally prove the system reliability Rs in

tests.

“The grass is always greener on the other side of the fence” said the Jackass, as it stretched its neck in the attempt to reach it.

Oscar Wlilde said: “Most men are other people. Their thoughts are some one else’s opinions, their lines a mimicry, their passions a quotation.”

We should remain true to our tradition and the ethos of the Indian culture. Yet we may accept certain good features of a foreign culture. Infact that is the beauty of our Indian culture which is a composite and our revolving culture. Our motto should be ADAPT but not ADOPT.